In 1976 we started with the trade and production of timber and later on in 1997 Mr. Cezmi Akca laid foundation to our Corum factory. Our factory which started manufacturing Plywood in 1998 became the most trusted & desired band in the region and known for not compromising our quality which is only possible due to our use of the best available matarial, high technology and most skillful hands.

The basics you need to know about Plywood is that it’s a sheet material which is brought to life by combining layers of wood veneer, which are glued together. Each adjoining layer is rotated up to 90 degrees in a process we call cross-graining. Why is this done? Well, the major reason is that it gives the product super strength. Thanks to cross-graining Plywood is able to resist splitting when nailed at the edges, minimise expansion and shrinkage and bump up its stability. Similarly, when cross-graining an odd number of layers will be used. This provides us with a balanced sheet that won’t easily warp.

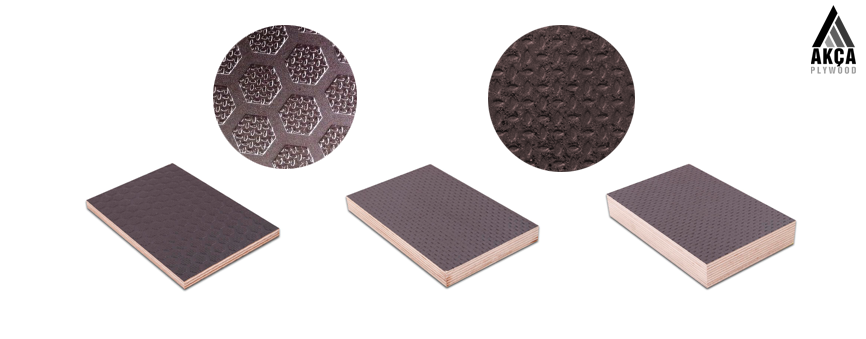

Film faced Pywood is lightweight, resistant to corrosion attack and water, easily combined with other materials and easy to clean and cut. Treating the film faced plywood’s edges with waterproof paint makes it highly water-and wear-resistant. Due to its durability and easily handled surface it can be used in open environment in construction and building e.g. warehouses, railway wagons, floors and sidewalls of trucks etc

We use phenol formaldehyde in our product (WBP).

Tree Types: poplar, pine, birch, eyong ,okume, etc..

Standard plywood boards are composed of an odd number of thin veneers glued together under pressure with the grain direction of the successive layers at right angles.

General purpose use for joinery, cabinet making, flooring.This hardwood non-structural plywood is suitable for a variety of general construction applications including ceilings and wall linings. It can also be used in furniture, temporary hoardings, non-structural packaging, kennels and more. Adequate sealing and wood treatment is recommended when used externally.

Tree Types: poplar, pine, birch, eyong ,okume, etc..

Akca Wood Floor is a wire mesh plywood used for flooring. The birch plywood is overlaid with multilayer phenol film with a rough wire mesh pattern. The rough-surfaced Akca Wood Floor is a heavy-duty, multipurpose, wire mesh plywood flooring panel for applications requiring a reliable, long-lasting anti-slip surface.

Akca Wood Floor is an ideal panel for transport applications that require highly wear-resistant and rough surfaces: van flooring, truck and trailer flooring, bus flooring, train flooring, ship decking and transport platforms. Akca Wood Floor can also be used in other heavy-duty flooring applications.

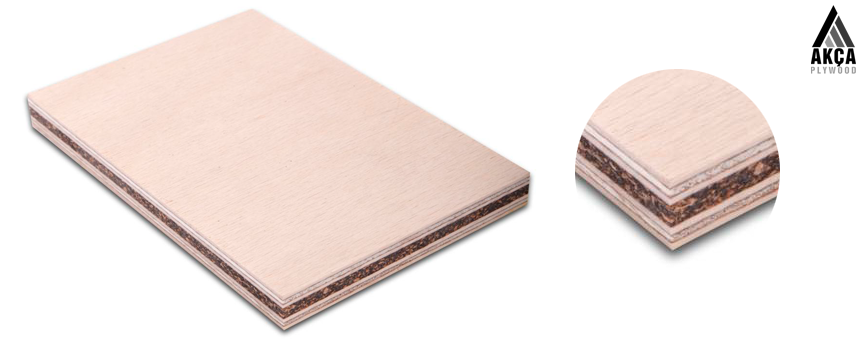

Akca Sound boards are composite structures made out of plywood and sound absorbing material. It is an ideal acoustic material for marine, railway and ground transportation.

Akca Sound is suitable for exterior and interior use. Lower fuel consumption reduced CO2 emissions can be achieved by using Akca Sound. The materials used in the board are free of hazardous substances such as PVC, heavy metals and formaldehyde.